100% Factory Testing, Guaranteed Quality Assurance

Finished product guarantee systemBefore mass production of new products, rigorous reliabilitytests are carried out, including 17 test items such asmechanical life, electrical life, overload, high and lowtemperature storage, constant temperature and humidity, etc.to verify the continuous operation ability of the product undernormal use conditions and extreme environments.

After the product enters the mass production stage, weconduct reliability tests every year to verify the performance ofthe product in actual operation.in addition, we perform typetest reports at different time intervals (may be monthly orsemi-annual)according to project requirements. Thissystematic testing and verification process is designed toensure that the product exhibits stable and reliableperformance in the market and meets customers’ strictrequirements for high-quality products.

Control quality from the source

Exploring Electrical Principles and Applicationsality from the source

Ensure relay reliability and safety under transient loads

Ensure Product Quality and Integrity

Ensure Environmental Friendlines

Key to Ensuring Long-term Stable Operation of Equipment

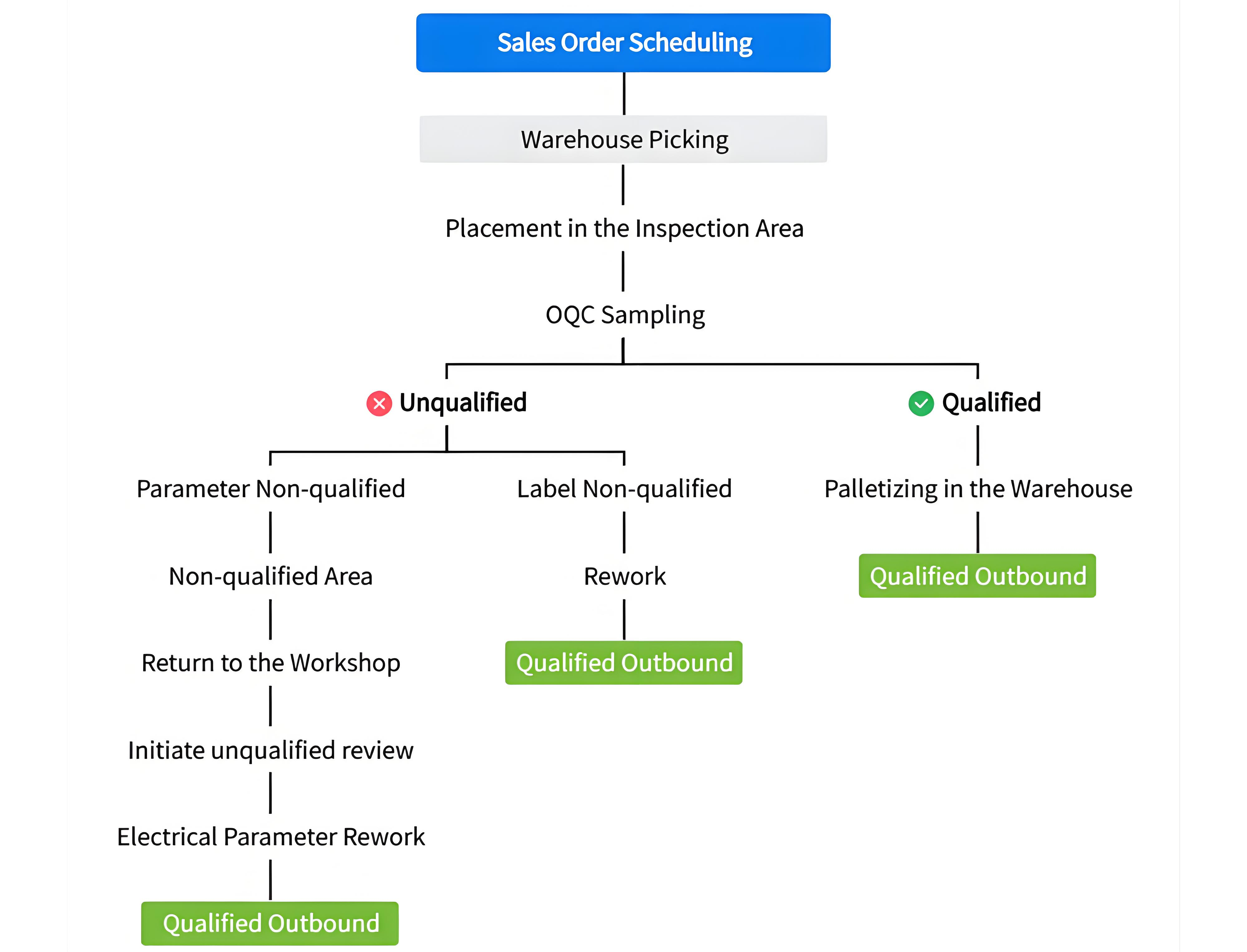

Meishuo’s quality inspection team comprises experts using advanced testing instruments and a robust management system to ensure each product meets stringent quality standards. Through scientific methods and ongoing improvements, we deliver high-performance, reliable relay products to our customers.

“By adhering strictly to industry standards, we guarantee that our deliverables consistently meet the highest quality benchmarks.”

Support your OEM/ODM needs and provide one-stop customized solutions