100% Factory Testing, Guaranteed Quality Assurance

Meishuo pays great attention to introducing advanced manufacturing technology and advanced production equipment in the industry. Through large-scale technology and equipment transformation, it has basically achieved full-automatic production capacity. The company now has 45+ fully automatic production lines, with a daily output of 2 million units and an annual output of 600 million units, achieving efficient production and strict quality control. It is one of the domestic relay production companies with a high degree of automation.

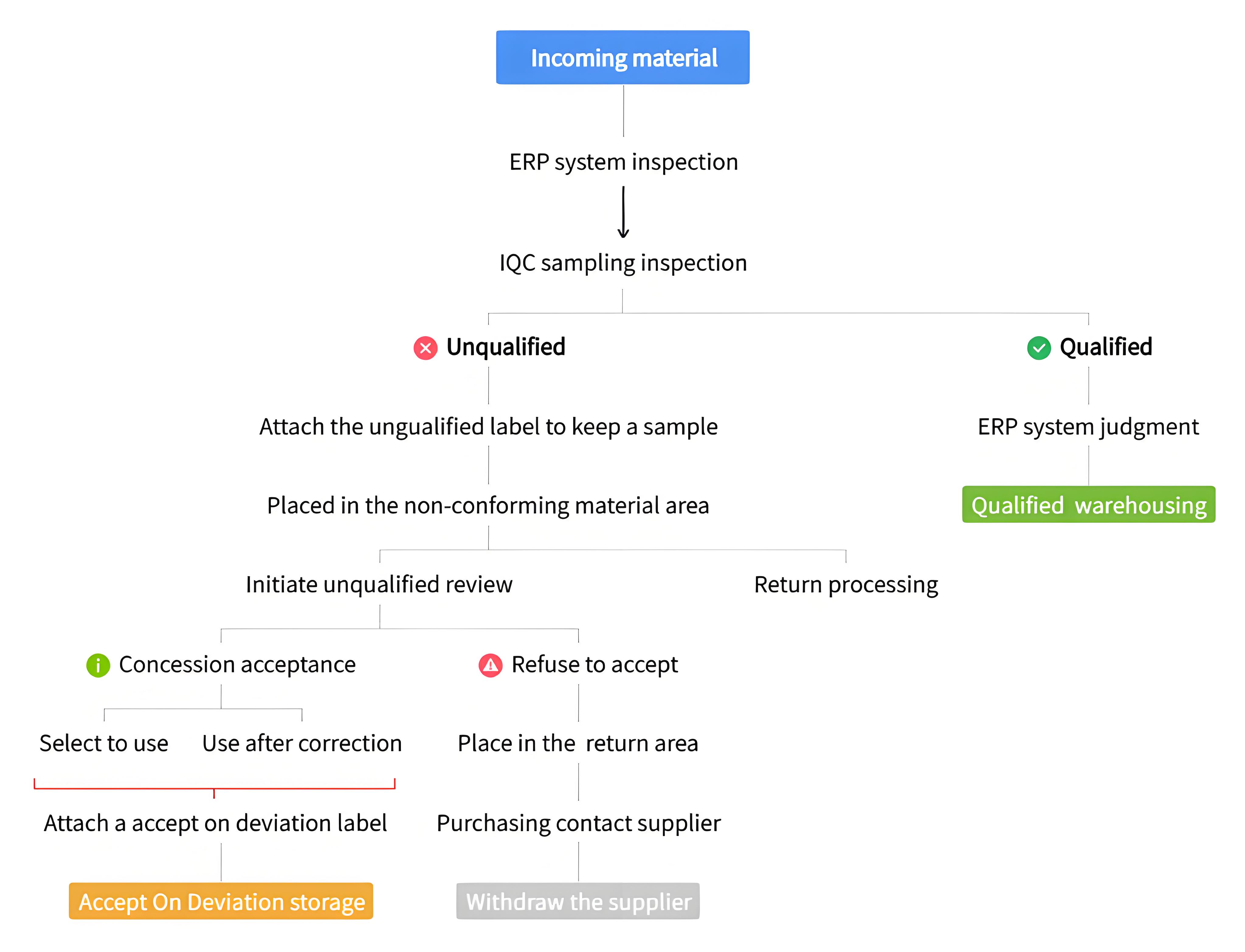

The Rigorous Incoming Material Control System is key to quality management, focusing on supplier segmentation and standardized inspections.

By refining supplier management, enforcing strict standards, and ensuring 100% traceability, we minimize production risks from material quality issues.

Over the past three years, we’ve maintained a 98% pass rate for incoming material inspections.

45+ fully automated production lines to avoid human errors and ensure product accuracy.

Daily output reaches 2 million pieces and annual output reaches 600 million pieces

Through ERP, MES, PLM system and digital panel control, create an intelligent workshop.

Use linear motors, CCD detection systems and high-precision sensors to perform 100% detection on key processes to ensure product quality.

“By adhering strictly to industry standards, we guarantee that our deliverables consistently meet the highest quality benchmarks.”

Support your OEM/ODM needs and provide one-stop customized solutions